First production 3D print!

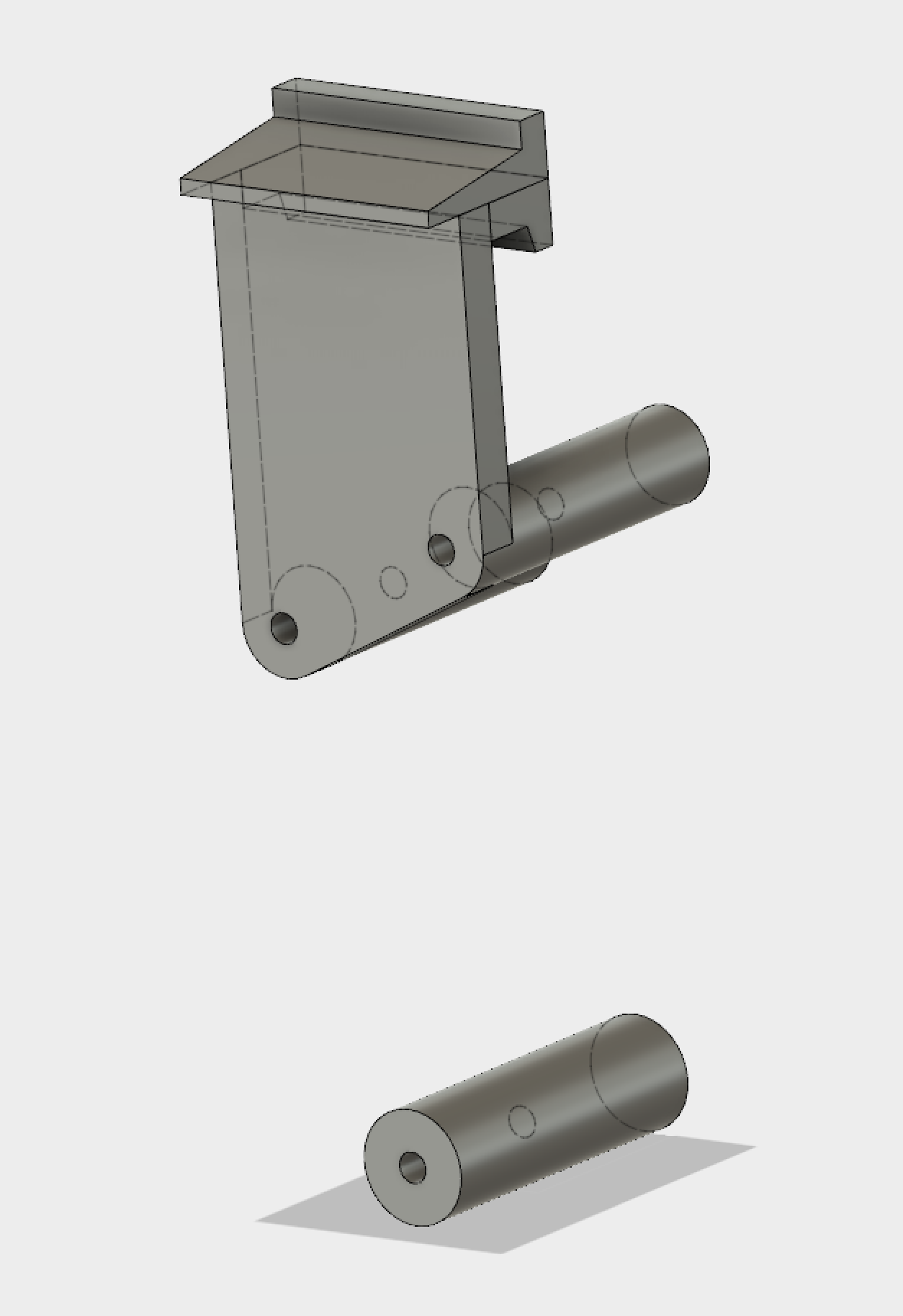

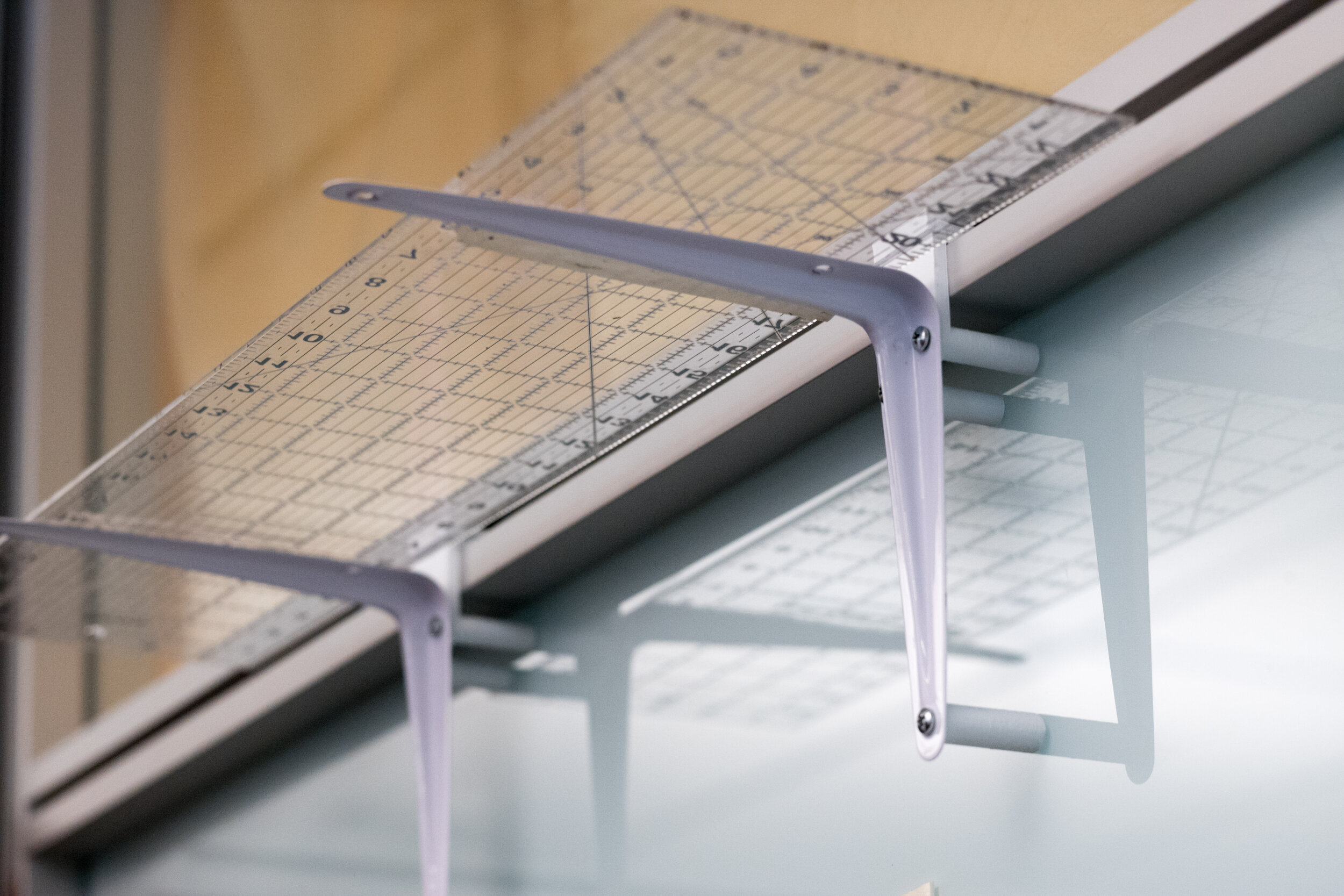

Ok, this is simple and boring. But the cool thing is that this is a solving a real-world need as opposed to making something for the sake of making it.My manager has a Lego motorcycle that he was displaying on a shelf that he taped to the wall. The problem is that the adhesive in the tape isn't as awesome as it could be. (Honestly, unless you get to construction adhesives that come with warnings, most tape isn't overly strong. It's kind of amazing that you can even buy cyanoacrylate glue over the counter, given how easily you can mess yourself up with it if you're stupid.)Anyway... I wanted to come up with a way of affixing the shelf holder to the rail on the wall. I was inspired by the coat hook that comes with the cubes that clips in to the same rail.I iterated a few times and came up with this design. Basically, there's an angled edge that catches the inside edge of the rail. Then I have a wedge that presses into that forcing it to not be able to back out. (In the CAD it's backward, it was supposed to be that way originally, but I realized that the tolerances would be annoying that way, and this way was a friction fit with a sliding surface which lets me avoid much of the tolerance stack-up.)He asked how much was it. Each side is 16g of filament. A total of around $0.06 worth of PLA. Maybe $0.20 if you count the throwaways prototypes.Or, of course, since this is the first two production parts to emerge from the Ultimaker... each one is $1500.10 for a total of $3000.20. ;-)Somehow I don't think that would go over too well on the expense report!

Ok, this is simple and boring. But the cool thing is that this is a solving a real-world need as opposed to making something for the sake of making it.My manager has a Lego motorcycle that he was displaying on a shelf that he taped to the wall. The problem is that the adhesive in the tape isn't as awesome as it could be. (Honestly, unless you get to construction adhesives that come with warnings, most tape isn't overly strong. It's kind of amazing that you can even buy cyanoacrylate glue over the counter, given how easily you can mess yourself up with it if you're stupid.)Anyway... I wanted to come up with a way of affixing the shelf holder to the rail on the wall. I was inspired by the coat hook that comes with the cubes that clips in to the same rail.I iterated a few times and came up with this design. Basically, there's an angled edge that catches the inside edge of the rail. Then I have a wedge that presses into that forcing it to not be able to back out. (In the CAD it's backward, it was supposed to be that way originally, but I realized that the tolerances would be annoying that way, and this way was a friction fit with a sliding surface which lets me avoid much of the tolerance stack-up.)He asked how much was it. Each side is 16g of filament. A total of around $0.06 worth of PLA. Maybe $0.20 if you count the throwaways prototypes.Or, of course, since this is the first two production parts to emerge from the Ultimaker... each one is $1500.10 for a total of $3000.20. ;-)Somehow I don't think that would go over too well on the expense report!